Introduction to LNG Full Containment Tanks

Release time:

2022-12-06

LNG full containment tankVarious faults are inevitably encountered during use. How should we analyze and solve these faults when they occur?

1. Stress analysis of LNG full containment tanks.

During the operation of the LNG full containment tank, the first few rows of heat pipes absorb heat to lower the external environmental temperature. After running for a period of time, the moisture attached to the surface of the heat pipes gradually freezes, reducing the heat exchange efficiency of the LNG full containment tank and affecting the vaporization effect. Therefore, the LNG vaporizer needs to be switched regularly during operation.

2. Causes of weld cracks in LNG full containment tanks.

LNG full containment tankThe top is a semicircular bend pipe, with no transitional straight pipe section, short dimensions, and large curvature. Under the action of thermal stress, the bend pipe's ability to compensate for deformation caused by thermal expansion and contraction is insufficient. The joint between the bend pipe and the finned straight pipe of the LNG vaporizer is a butt-welded joint, which is a weak point in strength.

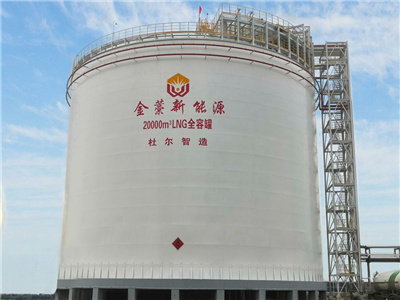

LNG is an ultra-low temperature liquid, and during use, transportation, and storage, specializedLNG full containment tankis used to store LNG.

1. Cold resistance

The boiling point of liquefied natural gas at normal pressure is -160. Choosing the low-temperature normal pressure storage method for LNG can lower the temperature of natural gas below its boiling point, allowing the working pressure of the storage tank to be slightly higher than normal pressure. Compared to high-pressure normal temperature storage methods, this can significantly reduce the wall thickness of the tank and improve safety performance.

Therefore, LNG requires that liquid storage tanks have good low-temperature resistance and excellent insulation performance.

2. High safety requirements

Since low-temperature liquid is stored in the tank, once an accident occurs inside the tank, the refrigerated liquid will evaporate in large quantities, with the vaporization amount being about 300 times that of the original refrigerated state, forming a gas cloud that can spontaneously explode in the atmosphere.

Therefore, standards such as API and BS require that storage tanks adopt a double-wall structure. When one layer of the tank leaks, the second layer can completely seal the leaked liquid and evaporated gas, ensuring storage safety.

LNG full containment tanks are low-temperature liquid storage tanks, which have strict manufacturing requirements.

1. Materials

The inner wall of the tank must be low-temperature resistant, generally using materials such as 9Ni steel or aluminum alloy.

2. Insulation measures

Since the temperature difference between the inside and outside of the tank can reach 200, to maintain the internal temperature at -160, the tank must have good insulation performance, and high-performance insulation materials should be filled between the inner and outer tanks. The insulation material at the bottom of the tank must also have sufficient load-bearing capacity.

3. Seismic performance

The general seismic requirement for buildings is to crack under specified seismic loads but not collapse. To ensure the safety of the tank under accidental loads, the tank must have good seismic performance. For liquefied natural gas storage tanks, they are required not to fall or rupture under specified seismic loads.

Additionally, the chosen construction site should generally avoid seismic fault zones. Before construction, seismic tests should be conducted on the tank to analyze its structural performance under dynamic conditions to ensure that the tank will not be damaged under the specified seismic intensity.

LNG full containment tank

Related

Duer Equipment Lights Up a New Ecosystem for Inland Waterway Shipping with LNG Fuel Tanks

As the philosophy of “Lucid waters and lush mountains are invaluable assets” takes root in the arteries of industry, green shipping is emerging as the core engine driving high-quality development of inland economic belts. Driven strongly by the nation’s policies on new-energy vessels, the market for inland new-energy ships is entering a golden period of rapid growth. On the Xijiang waterway in Guangxi, vessels equipped with LNG fuel tanks supplied by Nanyang Durr Gas Equipment Co., Ltd. are harnessing clean power to paint an ecological picture of “clear waters flowing smoothly.”

2025-11-27

On March 8, 2024, a milestone moment took place in the conference room on the fourth floor of Nanyang Doerr—the launch meeting for the Operations Management System project, co-hosted by Nanyang Doer and Zhongxu Education, was grandly held here. After in-depth interviews and careful preparations in the early stages, both parties have embarked on a new chapter of cooperation.

2024-03-08

The autumn is crisp and refreshing, with the fragrance of golden osmanthus in the air. On September 28, 2022, after intensive preparations, the intelligent production workshop project of the second phase of Nanyang Duer Gas Equipment Co., Ltd. officially entered the construction phase, marking the beginning of a high-tech intelligent production base. On this fertile land, the momentum is grand, and everything indicates a new vitality for the future of this land.

2022-09-28

Mid-Autumn Festival Charity: Deep Respect for the Elderly

On the morning of September 11, 2022, caring individuals from Nanyang visited the Le Ru Jia Elderly Service Center to offer Mid-Autumn Festival greetings.

2022-09-11

Devote love, great love knows no boundaries.

On the afternoon of September 5, 2022, Nanyang Du'er Gas Equipment Co., Ltd. donated to the 99 Charity Day event at the Civil Affairs Bureau of Sheqi County.

2022-09-06