Sub-mother tank

Sub-mother tank

Sub-mother tank refers to a storage tank in which multiple (three or more) inner containers (sub-tanks) containing medium are connected in parallel and placed in an outer container (mother tank) filled with insulating materials in a certain arrangement. It is generally designed and constructed for large-volume, pressurized storage.

inner container

The pressure vessel used to hold the medium is usually a vertical cylindrical leg structure.

Outer container

The outer metal shell that contains the inner container and forms a circular insulating interlayer with the inner container, usually a cylindrical flat-bottomed dome structure.

Product Details

inner container

The design and calculation of the structure, strength, etc. of the inner container body shall be carried out in accordance with the relevant regulations of GB150.

The inner container does not use vacuum leak detection, so there is no need to design for external pressure stability. However, considering that the diameter of the inner container is generally large, it is necessary to ensure the rigidity in its production and transportation engineering. Therefore, the inner container still needs to be equipped with reinforcement rings, and the distance between the reinforcement rings should be 2m~3m.

The inner container needs to be equipped with anti-vortex device and diffuser; the lower head leg needs to be equipped with stiffeners.

Inner container legs must adopt thermal insulation design, and the thickness of the epoxy glass cloth board shall not be less than 150mm. In order to ensure the static evaporation rate of the sub-tank and the piping space of the sandwich pipe, the height of the outriggers must be high enough (the height of the lower head of the inner container from the ground should not be less than 1500mm).

A cold bridge should be avoided to cause a short circuit of the cold capacity, and the connecting bolts of the outriggers should be provided with insulation gaskets. Through calculation, it should be satisfied that the temperature of the bottom plate of the outer container is not lower than the lowest temperature that the material of the bottom plate of the outer container can be used.

The seismic design and calculation of the inner container shall be carried out in accordance with the relevant provisions of SH3048 "Seismic Design and Calculation of Petrochemical Steel Equipment". The calculation process does not consider the influence of the pipe connection between the inner containers and the surrounding insulation materials.

Outer container

The design and calculation of the structure, strength, and external pressure stability of the outer container body shall be carried out in accordance with the relevant regulations of SY/T0608.

The connection between the low temperature pipeline and the outer container wall adopts the structure of vacuum tube and bellows.

configuration parameters

Volume: 300~3000m³

Pressure: 0.3~1.6MPa

Insulation method: Pearlescent sand accumulation and insulation

Number of canisters: 3, 4, 7, 10, 12

Design, manufacture, and acceptance standards

TSG R0004-2009 "Regulations for the Safety Technical Supervision of Stationary Pressure Vessels" Volume: 300~3000m³

GB150-1998 "Steel Pressure Vessel"

GB24511-2009 "Stainless Steel Plates and Strips for Pressure Equipment"

GB713-2008 "Steel plates for boilers and pressure vessels"

GB/T14976-2002 "Stainless steel seamless steel pipe for fluid transportation"

GB22724-2008 "Liquefied Natural Gas Equipment and Installation of Onshore Equipment Design"

GB50183-2004 "Oil and Natural Gas Engineering Design Fire Specification"

GB50084-2001 "Specification for Design of Automatic Sprinkler System"

JB4708-2000 "Qualification of Welding Procedure for Steel Pressure Vessels"

JB/T4709-2000 "Steel Pressure Vessel Welding Regulations"

JB/T4730-2005 "Non-destructive testing of pressure equipment"

SY/T0608-2006 "Design and Construction of Large Welded Low Pressure Storage Tanks"

SH3408-1999 "Code for Seismic Design of Petrochemical Steel Equipment"

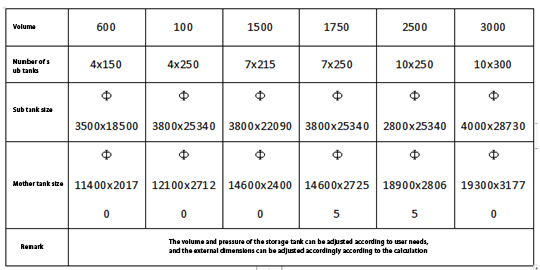

Specification Table

Nanyang Duer Gas Equipment Co., Ltd. is a joint-stock high-tech enterprise. The company is located in the picturesque north of the Han River and south of Funiu; the source of the South-to-North Water Diversion-Nanyang, the land of......

Contact us

Address:

South Section of Jingyi Road, Industrial Cluster District, Sheqi County, Nanyang City, Henan Province

Phone:

Mail:

Main products

Follow us

Copyright ©2020 Nanyang Doer Gaseous Equipment Co., Ltd 豫ICP备15028160号-53 Powered by: www.300.cn luoyang