What is the maintenance of LNG low-temperature storage tanks like?

Release time:

2022-02-15

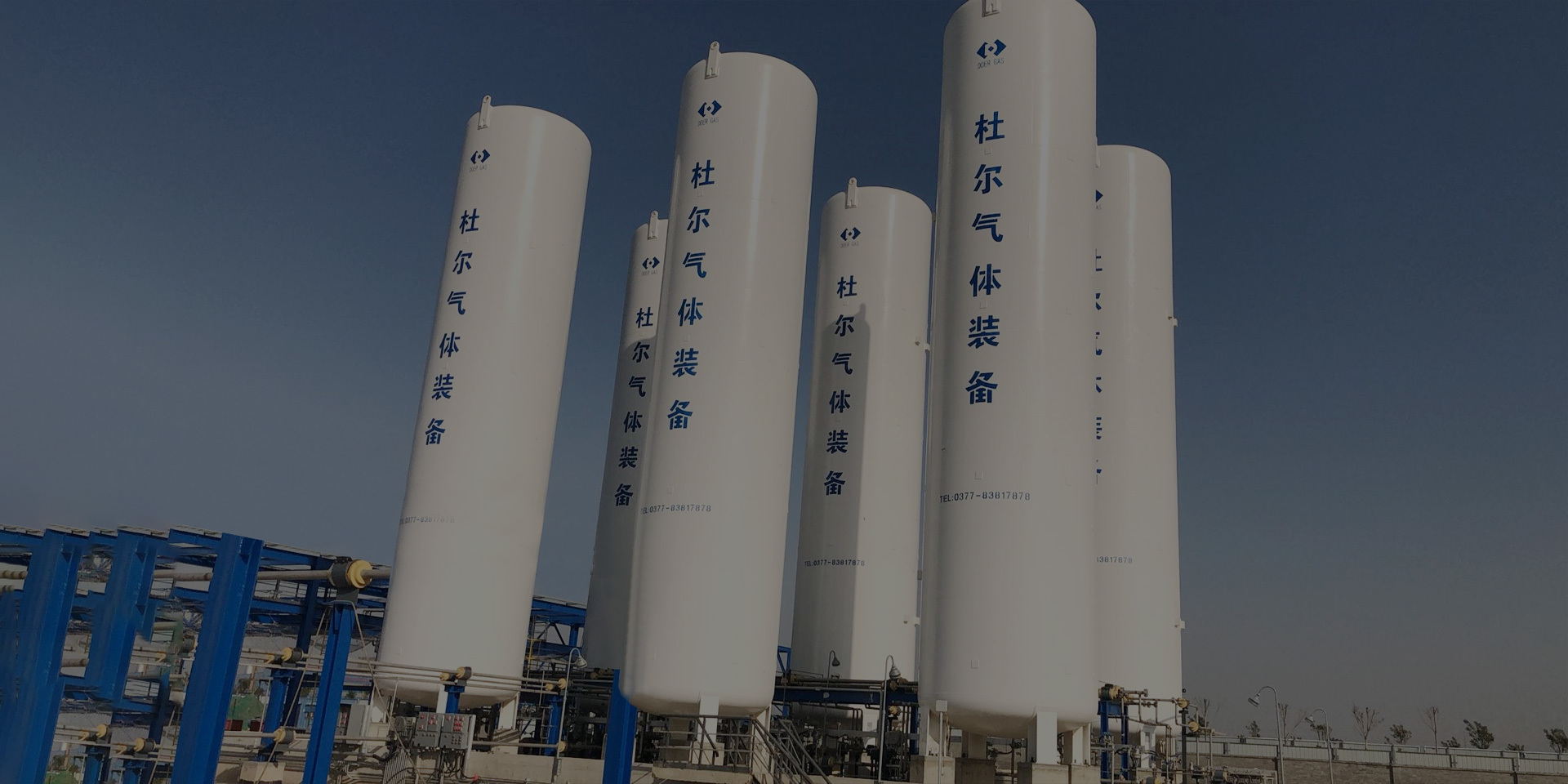

LNG low-temperature storage tankThe structure and types of LNG low-temperature storage tanks. In recent years, the low-temperature liquid market has been booming, with significant increases in the sales of liquid oxygen, liquid argon, liquid nitrogen, liquid carbon dioxide, and LNG natural gas. This has made the profitability of by-products from oxygen production very high, becoming an important component of imported products for steel enterprises. The production, storage, and transportation of low-temperature liquids rely on insulated storage tanks, which are widely installed and utilized.

LNG low-temperature storage tanks use a double-layer cylindrical structure, with the inner tank and its pipelines made of Wu's stainless steel, while the outer shell is made of carbon steel. The middle layer is filled with expanded perlite (also known as perlite sand), and a specially treated adsorbent is installed, extracted to a high vacuum (0.5~6Pa), with a capacity of less than 200 square meters. High working pressure (the two oil storage tanks at the bottom of workshop 4 have a working pressure of 2.0 Mpa), with a vaporizer outside the tank, making it easy to charge the tank with pressure. Depending on the purpose, they can be divided into fixed and transport types. The fixed type is mainly used for the storage of low-temperature liquids, set up at the production site, usage point, or supply station of low-temperature liquids. The transport type transports low-temperature liquids from the production or supply site to the usage site, usually by land or water transport, referred to as tank trucks, trailers, and tiger boats.

LNG low-temperature storage tankWhat is the maintenance like?

Common problem analysis and handling: The maintenance of the vacuum degree in the interlayer of the storage tank is the fundamental guarantee for the normal operation of the storage tank, while also ensuring the thermal insulation performance of the storage tank. Common issues after using the gas storage tank are related to the maintenance of the vacuum degree. There are obvious large areas of "sweat" and "frost" on the outside of the oil storage tank. Leakage in the pipelines of the middle layer of the oil storage tank, unfilled perlite sand, or other reasons may lead to damage to the interlayer vacuum degree. This requires checking, repairing, detecting leaks, and replenishing perlite sand, and vacuum can be re-extracted. The abnormal rise in pressure of the LNG low-temperature storage tank may cause the safety valve to activate. This may be caused by one of the following three reasons: a. Damage to the vacuum degree of the oil storage tank interlayer. b. The inner pipe pressure relief valve is not functioning and needs to be repaired or replaced. c. The outflow area at the interface where stainless steel is welded to the carbon steel shell or where the copper pipe connects to the stainless steel inner tank, i.e., at the dissimilar welding connection, mainly forms electrochemical corrosion at the dissimilar welding connection. (3) Increased evaporation and reduced vacuum degree. This may be due to the perlite sand being too coarse. Perlite sand has certain requirements for particle size and temperature during charging. When the particle size and temperature are not suitable, after running for a period of time, the perlite sand will release water vapor, thereby reducing the vacuum degree and increasing the evaporation.LNG low-temperature storage tank(4) "Sweat" at the top of the outer tank. It seems that the perlite sand is accumulating at the bottom. After being in use for a while, the perlite sand settles, creating space at the top of the container, significantly reducing the local insulation effect, making the container very cold. In this case, if the evaporation is large, perlite sand can be added to the top of the outer tank.

LNG cryogenic storage tank

Next Page

Related

Duer Equipment Lights Up a New Ecosystem for Inland Waterway Shipping with LNG Fuel Tanks

As the philosophy of “Lucid waters and lush mountains are invaluable assets” takes root in the arteries of industry, green shipping is emerging as the core engine driving high-quality development of inland economic belts. Driven strongly by the nation’s policies on new-energy vessels, the market for inland new-energy ships is entering a golden period of rapid growth. On the Xijiang waterway in Guangxi, vessels equipped with LNG fuel tanks supplied by Nanyang Durr Gas Equipment Co., Ltd. are harnessing clean power to paint an ecological picture of “clear waters flowing smoothly.”

2025-11-27

On March 8, 2024, a milestone moment took place in the conference room on the fourth floor of Nanyang Doerr—the launch meeting for the Operations Management System project, co-hosted by Nanyang Doer and Zhongxu Education, was grandly held here. After in-depth interviews and careful preparations in the early stages, both parties have embarked on a new chapter of cooperation.

2024-03-08

The autumn is crisp and refreshing, with the fragrance of golden osmanthus in the air. On September 28, 2022, after intensive preparations, the intelligent production workshop project of the second phase of Nanyang Duer Gas Equipment Co., Ltd. officially entered the construction phase, marking the beginning of a high-tech intelligent production base. On this fertile land, the momentum is grand, and everything indicates a new vitality for the future of this land.

2022-09-28

Mid-Autumn Festival Charity: Deep Respect for the Elderly

On the morning of September 11, 2022, caring individuals from Nanyang visited the Le Ru Jia Elderly Service Center to offer Mid-Autumn Festival greetings.

2022-09-11

Devote love, great love knows no boundaries.

On the afternoon of September 5, 2022, Nanyang Du'er Gas Equipment Co., Ltd. donated to the 99 Charity Day event at the Civil Affairs Bureau of Sheqi County.

2022-09-06